Table of Contents

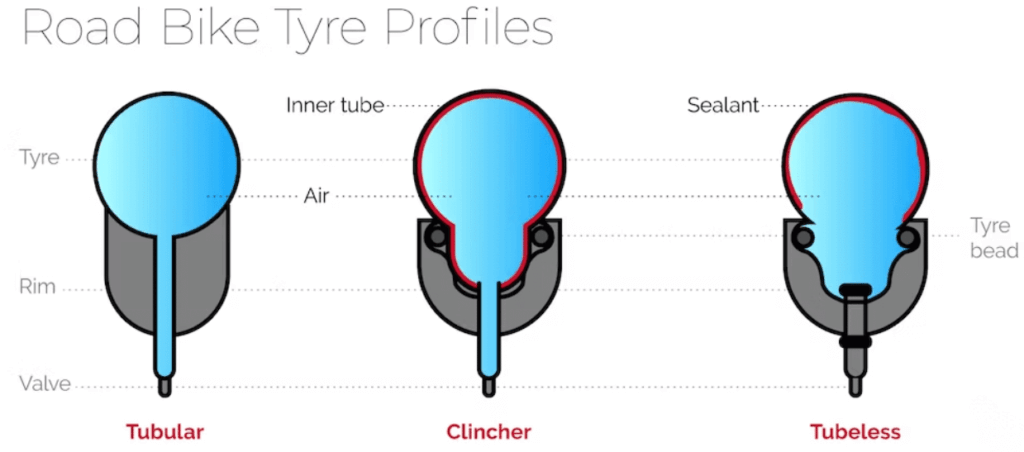

For decades, road cyclists have relied on traditional clincher tires with inner tubes. However, in recent years, there’s been a significant shift towards tubeless road bike tires. You may have heard about tubeless bike tires, but you might be confused about them or reluctant to make the change.

This evolution has been driven by advancements in tire technology, offering cyclists a host of benefits, including enhanced puncture resistance, reduced rolling resistance, improved comfort, and better traction.

If you’re intrigued by the idea of tubeless road bike tires but unsure where to start, this comprehensive guide will explain the pros and cons, giving you a better idea if you should take the plunge and change over.

Why Tubeless Tires Are Gaining Popularity

The cycling industry is always evolving, and one of the most significant changes in recent years has been the widespread adoption of tubeless road bike tires. So, what’s driving this shift in popularity?

In this article, we’ll explore the key reasons behind the growing preference for tubeless tires among road cyclists.

First and foremost, tubeless tires offer a solution to a common problem that has plagued cyclists for generations: flat tires caused by punctures and pinch flats.

With traditional clincher tires, the inner tube is susceptible to pinching between the tire and the rim, especially at lower tire pressures. This can result in a flat tire and a frustrating interruption to your ride.

Tubeless tires eliminate the need for inner tubes altogether, significantly reducing the risk of pinch flats.

Advantages of Tubeless Tires

Say goodbye to pinch flats and punctures. Tubeless tires offer several advantages that make them appealing to road cyclists.

1. Enhanced Puncture Resistance: Perhaps the most significant advantage of tubeless tires is their resistance to punctures. Traditional clincher tires can be prone to flats caused by sharp objects on the road, like glass shards or thorns. In contrast, tubeless tires rely on sealant to fill and seal punctures as they occur, allowing you to keep riding without interruptions.

2. Lower Rolling Resistance: Rolling resistance is the force that slows down your bike when you’re pedaling. Tubeless tires typically have lower rolling resistance compared to their clincher counterparts, thanks to their ability to run at lower pressures without the risk of pinch flats. This means you can go faster with less effort.

3. Improved Ride Comfort: With the ability to run lower tire pressures, tubeless tires provide a more comfortable ride. The increased cushioning effect not only absorbs road vibrations but also enhances your overall riding experience, especially on rough or uneven terrain.

4. Better Traction: Tubeless tires can offer improved traction, particularly when cornering or riding on wet roads. The lower tire pressures allow for a larger contact patch with the road, increasing grip and stability.

5. Weight Savings: Tubeless setups can be lighter than their clincher counterparts. The absence of inner tubes and the ability to use lighter rims can contribute to reducing the overall weight of your bike.

6. Reduced Risk of Blowouts: Traditional inner tubes are more susceptible to sudden blowouts when they fail. Tubeless tires, on the other hand, tend to lose air gradually, giving you more control and safety in case of a puncture.

Disadvantages and Myths

Addressing common misconceptions. While tubeless tires have many benefits, there are also some misconceptions and drawbacks that have deterred some road cyclists from making the switch. Let’s address these concerns and separate fact from fiction.

1. Initial Setup Complexity: One common misconception is that setting up tubeless tires is complicated and requires special skills. While there is a learning curve, especially for first-time users, the setup process is manageable with the right guidance.

2. Sealant Maintenance: Some cyclists worry about the need to maintain tubeless sealant. It’s true that sealant can dry up over time, but topping it up is a straightforward task that doesn’t require frequent attention.

3. Limited Tire Options: In the past, the variety of tubeless tire options was limited, but the market has expanded significantly. Today, you can find a wide range of tubeless-ready tires suitable for various riding conditions and preferences.

4. Burping and Air Loss: Burping, which is the sudden release of air from the tire when cornering aggressively, can be a concern for some riders. However, it’s more common with mountain bike tubeless setups than road setups. Proper tire and rim compatibility, as well as adequate tire pressure, can minimize this issue.

5. Weight and Cost: While tubeless setups can be lighter, they can also be more expensive initially due to the need for tubeless-compatible rims and tires. However, the long-term benefits often outweigh the initial investment.

6. Conversion Challenges: Converting existing clincher wheels to tubeless can be challenging, and not all rims and tires are suitable for conversion. It’s essential to check compatibility and follow specific guidelines when attempting a conversion.

Essential Components and Tools

Tubeless-Ready Tires

Choosing the right tires for your road bike is crucial. Tubeless-ready tires are specially designed to work without inner tubes and have a stronger bead that ensures a secure fit on tubeless-compatible rims. These tires have a unique bead shape and casing that facilitates airtight sealing when installed on compatible rims.

When selecting tubeless-ready tires, it’s essential to consider factors like tire width, tread pattern, and compound to match your riding style and terrain. Many manufacturers offer tubeless-ready versions of their popular road tires, giving you a wide range of options to choose from.

Tubeless-Compatible Wheels

Matching the tires with the right rims is essential for a successful tubeless setup. Tubeless-compatible rims have specific design features that make it easier to create an airtight seal with the tire bead. Here are some key characteristics to look for in tubeless-compatible wheels:

1. Bead Hook Design: Tubeless-compatible rims often feature a bead hook design that helps secure the tire bead in place, preventing air leaks and burping during aggressive riding.

2. Airtight Rim Tape: Tubeless-compatible rims come with airtight rim tape pre-installed or provide suitable rim tape for sealing the spoke holes. Proper rim tape installation is crucial to prevent air from escaping through the spoke holes.

3. Tubeless Valve Compatibility: Tubeless-compatible rims should have valve holes that fit tubeless valve stems. These valve stems are designed to create an airtight seal with the rim.

When purchasing new wheels, ensure they are labeled as tubeless-compatible or tubeless-ready to avoid compatibility issues.

Tubeless Sealant

The key to a successful tubeless setup is tubeless sealant. This liquid substance is injected into the tire, where it serves multiple functions:

1. Sealing Punctures: Sealant is the primary defense against punctures. When a foreign object, like a nail or thorn, pierces the tire, the sealant instantly seals the hole to prevent air loss.

2. Maintaining Tire Pressure: Sealant helps maintain tire pressure by sealing minor air leaks caused by porosity in the tire casing or at the tire-rim interface.

3. Balancing Tire Wear: Sealant can also help balance the tire by evenly coating the inside, ensuring consistent tire wear and performance.

Sealant typically lasts several months before needing replenishment, depending on factors like temperature, humidity, and riding conditions. It’s crucial to check and replenish the sealant as needed to maintain optimal tubeless performance.

Tubeless sealants are available in various formulations and viscosities, so you can choose one that best suits your needs. Some sealants also contain particles or fibers to better seal larger punctures.

Tubeless Valves and Rim Tape

Tubeless valves and rim tape are small but critical components in a tubeless setup. Here’s what you need to know about them:

Tubeless Valves: Tubeless valves are essential for creating a sealed passage between the tire and the outside air. These valves consist of a valve stem, valve core, and valve cap. The valve stem passes through the rim’s valve hole, while the valve core can be removed for injecting sealant into the tire. A snug-fitting valve cap keeps dust and debris out.

Rim Tape: Rim tape is applied to the rim bed to seal the spoke holes, preventing air from escaping through them. Proper rim tape installation is crucial for airtightness.

Tubeless-compatible rims often come with suitable rim tape pre-installed, but you may need to apply it yourself if it’s not included.

When selecting tubeless valves and rim tape, ensure they are compatible with your rims and tires. Some valves have different lengths to accommodate different rim depths, while rim tape should match the internal width of your rims.

Should You Make the Change to Tubeless Road Bike Tires?

Now that you’ve gained insight into the world of tubeless road bike tires and how to install and maintain them, you might be wondering if it’s the right move for you. Making the switch to tubeless tires is a decision that depends on your individual cycling preferences and needs.

Benefits: The advantages of tubeless road bike tires are hard to overlook. They provide enhanced puncture resistance, lower rolling resistance, improved ride comfort, and better traction, making them an attractive option for many cyclists. Additionally, the reduction in the risk of pinch flats and blowouts can offer peace of mind during your rides.

Drawbacks: However, it’s essential to consider some potential drawbacks. The initial setup can be slightly more involved than traditional clincher tires, and the cost may be higher due to the need for tubeless-ready rims and tires. Maintenance, such as replenishing sealant, is also required periodically.

Opinion: In our view, if you’re seeking to take your cycling experience to a new level, making the switch to tubeless road bike tires is a worthwhile investment. While there might be a learning curve initially, the benefits, such as fewer flats, reduced rolling resistance, and a more comfortable ride, often outweigh the drawbacks.

The enhanced traction and puncture resistance allow you to push your limits on various terrains, and the confidence of knowing that you’re less likely to experience a flat tire can lead to more enjoyable and stress-free rides.

Ultimately, the decision to go tubeless depends on your cycling goals, but for those seeking an upgrade in performance and comfort, tubeless road bike tires are a game-changer.

FAQ About Tubeless Road Bike Tires

Can tubeless road bike tires go flat?

While tubeless road bike tires are less prone to flats caused by punctures and pinch flats, they can still lose air over time due to slow leaks or other issues. Regularly check your tire pressure and inspect your tires for any visible damage or leaks to ensure they remain properly inflated.

Are tubeless road bike tires faster?

Tubeless road bike tires can be faster due to their lower rolling resistance. The absence of inner tubes and the ability to run at lower pressures without pinch flats can lead to improved speed and efficiency.

Can I use tubeless road bike tires on any type of road surface?

Tubeless road bike tires are versatile and can be used on various road surfaces, including smooth pavement, rough roads, and gravel. However, the ideal tire type and pressure may vary depending on the terrain. For rougher or gravel roads, you may want to choose wider tubeless tires with lower pressures for improved comfort and traction.

Can I repair a tubeless road bike tire with a traditional patch kit?

Traditional patch kits designed for inner tubes may not work effectively on tubeless road bike tires because of the sealant inside the tire. It’s recommended to use a tubeless-specific tire patch kit for repairing tubeless tires, as these kits are designed to work with sealant and provide a reliable fix.

Are tubeless road bike tires more expensive than traditional clincher tires?

Tubeless road bike tires can be more expensive than traditional clincher tires due to the additional technology and manufacturing processes involved in creating tubeless-compatible tires. However, the cost difference can vary depending on the tire brand, model, and features.